Home (contents) → Chronology → Hang gliding 1978 and 1979 part 2

Hang gliding 1978 and 1979 part 2

This page follows Hang gliding 1978 and 1979 part 1.

The images on this page are mostly artistic derivations of contemporary photos. See Copyright of early hang gliding photos.

A colour photo of Liz flying her Condor appears on the next page and there is an external link to an article about her farther down this page.

Another lady pilot, this time in South America, was Paula Vieria. The Phoenix 6C was another Bennett wing designed by Dick Boone. See also the Dick Boone, hang glider designer and Bill Bennett’s Delta Wing Kites and Gliders related topics menus.

Developments 1978-9

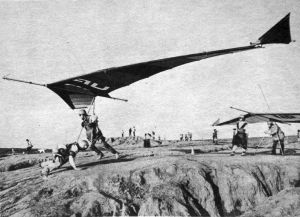

The Eagle was a prototype that Tom Peghiny made while at at Seagull Aircraft. (See the Seagull Aircraft related topics menu.) The adding of a tail was partly driven by the increasingly popular Soarmaster bolt-on power unit at this time. If you stalled the wing under power, its high thrust line caused a pitch-over, hence the need for greater pitch stability and dive recovery. (See Early powered ultralights part 1 for more about the Soarmaster power unit.) The simple V configuration of the Eagle tail was easier and quicker to rig than a three piece design.

The zero sweep design of the Eagle was similar to that of the Markowski Eagle III (see Scientific American hang glider).

These variations arising from the struggle for greater performance combined with adequate stability and controlability, all without adding too greatly to the cost of manufacture and effort of rigging, did not make it into production. Yet, according to Tom Peghiny, the Jaguar (derived from the Eagle) would make a good motorglider combined with one of today’s paraglider power units.

For the immediate successor of the Eagle, see Jaguar in Hang gliding 1978 and 1979 part 3. See also the Flex-wings with tails and Tom Peghiny related topics menus.

Here, the wind on the sail has taken some of the pilot’s weight: Notice the upward curve of the leading edges, which were straight when the Mosquito was unloaded.

In 2012, long time instructor Ken De Russy sent me several American hang gliding magazines and books pre-dating my own collection. They provided much information I drew on for this web site. See the Santa Barbara Hang Gliding Emporium page for more.

The UP Mosquito was unique in its combination of forward-canted king post, triangular tip fins, and heavily bowed leading edges. A British pilot reported that the leading edge tubes were straight, but when launching in light wind, they took up their curved alignment part way through the launch run with an alarming clunk!

For a link to Richard Cobb’s comprehensive UP Mosquito page, see the related topics menu Ultralight Products of California and Utah. See also the Torrey Pines page.

The Mitchell Wing was a tail-less monoplane in which aerodynamic stability is built into the wing (mostly…) as is the case with most flex-wing (Rogallo) hang gliders. Unlike most other rigids of the time, the Mitchell Wing was ‘cantilevered’; its structural strength was built inside the wing rather than relying on external struts and cables.

George Worthington, a former US Navy pilot, became a world distance record-holder in his fifties and sixties flying a Mitchell Wing as well as flying flex-wing hang gliders in the Owens valley.

See the Mitchell Wing page for more.

Moyes Gliders of Australia was among the top manufacturers then, as now (2021) opening a facility in the U.S.A. to meet demand. See also the Moyes related topics menu.

Vehicle-based testing

While sandbag testing of single surface gliders suspended upside-down is effective (refer to the related topics menu Testing for stability and structural strength) there is a particular problem with sandbag testing of double surface sails: You cannot reach the underside of the upper surface to put sandbags on it. Even if you could — and even if there was enough room — how many sandbags should you place on the lower surface to add an ‘upward’ (downward in the Hiway upside-down test) force on the cross-tubes?

That was one impetus behind hang gliding associations in several countries creating structural and pitch stability test rigs. They included the Hang Glider Manufacturers Association in the USA, the DHV in Germany, and the British Hang Gliding Association.

Co-author of Aerodynamic Test System in the March 1981 Glider Rider Thierry Guignard was of Highster Aircraft, manufacturer of a double-surface flex wing similar to the Sky Sports Sirocco, both predating the Comet.

I don’t know of anyone, inside or outside of the hang gliding industry, who is capable of doing an accurate structural analysis of a flex wing hang glider; the loading situations are far too complex and varied.

— Mike Meier of Wills Wing writing in Hang Gliding, June 1983, to explain why rigorous testing is required

There is more about Gary Valle of Sunbird and their deflexorless Nova later on this page. See also the Computing in hang gliding related topics menu.

Sail painting

Compare with the (almost) blank canvass…

The Seagull factory was still making gliders with curved leading edges.

The Seagull Seahawk mark 2 had more battens than its predecessor. The artwork on the sail of this example was carried out by Donna Lifsey. See also the related topics menus Hang glider sail art and Seagull Aircraft of Santa Monica, California. See Early powered ultralights part 1 for more about the Soarmaster power unit.

Jim Johns did not need an engine, however. On 18 April 1980, he flew his un-powered hang glider (in free flight as we call it) from 134 foot-high Jockey’s Ridge, North Carolina, 4.5 miles down wind to land near the Wright memorial.

The Seagull Seahawk held a long-standing reputation for its handling qualities throughout launch, flying, and landing.

I will never forget the first time I flew a new one. It had perfect static balance, was lightweight, and with a good run I was off. The glider was in trim: It needed no pilot. With easy predictable control, I was in love even before I had come to a gentle landing.

–Doug Rice, Glider Rider, November 1980

The hang glider name Phoenix was effectively monopolized by Bill Bennett’s Delta Wing Kites and Gliders of Van Nuys, California. Bennett’s designer at this time was Dick Boone. I have no info about who created the sail art in this example. See also the Dick Boone, hang glider designer and Bill Bennett’s Delta Wing Kites and Gliders related topics menus.

The pilot here is Jeff James and the glider is an AeroStar Starcraft made in Boone, North Carolina. The airframe was made of 1 1/2 049 tubing, making it very light. This is a later version after deflexors were added. (3)

See the Hang glider sail art related topics menu. Also see under External links later on this page for video in color of George Worthington’s Cumulus VB with dragons painted on the sail.

Engineering

Manta, based in Oakland, California, manufactured the Fledge 2 ‘semi rigid’ hang glider, which at this time was unbeatable in competition. However, a flex-wing was under development by a rival manufacturer that was to nullify the Fledge’s advantage. The Manta Fledge 2, like the Eipper Quicksilver, subsequently gained a new lease of life as a powered ultralight. (See Early powered ultralights.) Manta also manufactured components for other powered ultralight manufacturers. See the Manta Products of California related topics menu.

George Worthington was a retired navy pilot who held world distance records in both rigid and flex-wing hang gliders. (See the Mitchell Wing page for more of Worthington.) Tom Peghiny started designing and building his own hang gliders while still at school. Dennis Pagen writes the most authoritative texts about every aspect of hang gliding.

Bob Calvert was the top ranked British pilot at the time. Derek Evans managed the British competition team.

Dennis Pagen, a prolific author of hang gliding technical articles and books, was U.S. champion in 1978 flying a Sky Sports Sirocco II, which he partly designed. For more about this east coast manufacturer, see Flying squad. See also the Dennis Pagen related topics menu.

The first generation of enclosed cross-bar gliders like the Sirocco, Mariah and Highster … failed to compete with the Raven generation and later gliders.

— Wills Wing designer Steve Pearson, referring to the ill-fated Bennett Phoenix Mariah (see Mariah in Hang gliding 1978 and 1979 part 3), the Highster (made in Berkeley, California), and single surface — but deflexorless — Wills Wing Raven, about which more later on this page. (7)

For another experience of the relative merits of some of these wings, see the comment by Chris Gonzales later on this page.

In early 1979, the Lancer IV, originating in New Zealand, epitomized the state of the art for the average flex-wing pilot. (See Marty Alameda and Flight Designs.) However, as was normal in hang glider technology development during this period, its pre-eminence did not last long. A new wing designed in France was about to consign all previous flex-wings to history. Then, a further development in California made that design redundant too, at least among top performing flex-wings.

In the USA, Peregrine Aviation pushed the ‘truncated tip’ single surface flex wing to its limits with the Owl. This one has fairings to reduce the aerodynamic drag of the cross-tubes. However, the design was by late 1979 dated by its triple leading edge deflexors, which comprised a hidden cause of much drag. The multi-line harness, stand-up keel pocket, and absence of an enclosed space to store a glider bag were additional drag-inducing aspects that were dealt with in the next few years.

Most of the innovations in hang glider sails — high aspect ratios, battens, applied trailing edges and cambering — aren’t really innovations at all. They’ve been commonplace techniques in sail lofts for years. We learned from them, modifying their methods to the peculiar needs of our own sails. The offspring of this marriage is both sail and wing.

Your Sail – More Than Color and Shape by John LaTorre, Hang Gliding, October 1980

John LaTorre had been instructing and selling and repairing gliders in Maryland, eastern Pennsylvania, and northern Virginia, but the harsh winter of 1977-8 shut down the business for which he worked…

I had just turned thirty, and not only was I jobless, but it fell to me to tell all our customers that there would be no refunds for pre-paid lessons or deposits on gliders.

Fortunately, Electra Flyer of New Mexico was hiring…

Five days later, at around midnight, I pulled into a UPS parking lot on the north side of Albuquerque, drew the curtains, and slept. The next morning, I found the factory and claimed the job.

— John LaTorre (1)

LaTorre was soon in charge of the Electra Flyer sail loft, the beginning of a 15-year stint as a sailmaker, at one point with thirty people working for him in two shifts. He picked up sailmaking techniques from Tom Price and Tom Peghiny, who were working as designers at Electra Flyer. See also the John LaTorre related topics menu.

Back to the future

In early 1979 Tom Price, then working for Electra Flyer while its owner was away on a Transatlantic balloon adventure, initiated the removal of the drag-inducing and complex leading edge deflexors that had proliferated since the mid 1970s. Like the first standard Rogallo flex-wings, the leading edges were ‘cantilevered’, that is they relied on beefier leading edge tubes for strength and stiffness rather than external bracing. It was a design trend that all manufacturers quickly adopted, including Ultralight Products, whose Comet was about to further revolutionize hang glider design.

The initial wave of deflexorless gliders was the Floater 205 (a great glider but with an inappropriate name, it was fast rather than slow), the Raven which became the most popular glider world-wide at the time, and the Nova which was very nice flying and performing glider but never achieved as much commercial success as competitors.

— Wills Wing designer Steve Pearson (4)

There is more about the Wills Wing Raven a little later.

A counter claim of the re-introduction of defexorless leading edge tubes is made on behalf of Ultra Light Flight Systems in Sydney, Australia, whose designer Steve Cohen developed the Skydart. The Skydart retained the ventral fin of Steve Cohen’s earlier SK2 (and the British Hiway Scorpion). That blend of old and new lends support to the possibility that the Skydart led the way in the mid- to late 1970s reintroduction of deflexorless leading edges. In this author’s opinion, 1977 seems the likely year. (8)

The Sunbird Nova was designed by aerodynamicist Gary Valle partly in response to the pitch-over emergency of the late 1970s. It featured an unusually long (for the late 1970s) root chord.

While HGMA records(5) indicate that the Electra Flyer Floater and Sunbird Nova were first of the late 1970s deflexorless designs to be certified — both being certified on the same date — Sunbird claims that the Nova was the first of the new deflexorless types to fly and to go into production, having been ‘introduced’ in the summer of 1978. (6)

The Spirit was successor to the Floater.

See also Tom Price’s flying machines and the related topics menus Electra Flyer of Albuquerque, New Mexico, and Larry Newman and Hang glider sail art.

Fly straight with perfection

Find me a new direction

— From the lyrics of The Raven by the Stranglers, 1979

In 1979, Wills Wing, just one of the several hang glider manufacturers based in California, replaced their three production hang glider types, the Omega, Omni, and Alpha, by a single defelexorless design; the Raven. Wills Wing made nearly 1,500 Ravens. (See Wills Wing glider production history.)

The Skyhawk was successor to the single surface Harrier (an advanced wing) and Raven. Notice the absence of deflexors along the leading edges, with their cables, adjusters, supporting struts, and attachment fittings. All gone! Even the outer ends of the crosstubes and their attachments to the leading edges are tucked away into the slower moving air close to the underside of the sail.

Erik Fair, shown here demonstrating correct landing flare technique, wrote an entertaining instructional book, a compilation of his series of articles in Hang Gliding magazine.

In this image the creases in the left (underside) leading edge pocket, caused by differential span-wise tension between the leading and trailing edges, create an incorrect impression of the camber of the sail, incidentally. The orientation of the batten pockets provides an accurate indication.

See also the Sport Kites/Wills Wing of California related topics menu.

Dove

Dove: Past tense of dive 😀

Hang glider manufacture is intolerant of even apparently trivial changes. Every change must be tested. This sub-section describes a problem with a prototype licence-built Electra Flyer Dove, and its solution.

The Electra Flyer Dove was a beginner rated single-surface wing with the latest 1979 features: Absence of deflexors and the addition of short anti-flutter battens at the tips. All modern hang gliders (in 2020) incorporate the former (that is, they are without deflexors) and some also include short anti-flutter battens.

The first prototype of the Scotkites/Eurowing license-built Dove (with UK aluminium tubes and a sail made in the U.S.A.) flew just like American made Doves; at least in light winds. However, when two test pilots tried it in stronger conditions, they found that pulling on speed caused the nose to drop alarmingly. It was puzzling because the new frame was a good match for the original.

Some ‘wind tunnel’ testing on top of the hill in a strong breeze illustrated that a slightly loose fit of the sail at the nose and the flexibility of the plastic center batten caused the problem. When the angle of attack was reduced enough, the sail at the nose blew down, radically altering the airfoil curve and introducing a nose-down pitch force. (The nose batten was held up by a cord attached to the front top rigging cable, and in the unstable state it changed from a convex curve to an S shape…)

After Scotkites repositioned the sail and fitted a stiffer nose batten, the docile flying characteristics of the Dove returned. (2)

For more about the problem of dive recovery in a weight shift controlled flying machine, see Luff in the time of cholera (a whole topic about the luffing dive) and Vehicle-based testing in Tom Price’s flying machines, where ‘pitch feel’ tests were carried out with the hang glider tethered to the top of a moving vehicle instead of sitting on a windy hillside.

See also the Electra Flyer of Albuquerque, New Mexico related topics menu.

Cyclone and Vortex

Chargus of Buckinghamshire, England, used a cross-tube rather than a bowsprit and cables despite the wide nose angle of the high performance Cyclone.

See Pete Harvey’s comment in Hang gliding early 1980s part 1 for evidence that one particular Cyclone might have been the first to benefit from the ‘floating keel’, which subsequently became the norm in flex-wing design.

The Vortex intermediate level wing, which came in 110 degree and 120 degree nose angle variants, featured an array of small holes in the sail toward each wing-tip to improve its resistance to tip stalling. (The Cyclone might also have had similar holes.)

Technical: Notice the cable from the centre to the near wing tip. (The one the other side is hidden by the right down-tube.) These ‘bow strings’ limited the flex of the leading edges in the opposite way of the earlier deflexor systems — cables on struts along the leading edges. The hang strap has a pitch limiter, similar to that used on the Skyhook Cloud 9, but the Chargus version seems to be made of cable rather than webbing. (Webbing provides better resilience to shock loading.)

The pilot in the photo is David Parsons, Justin’s father, who died in 2019.

Author’s reminiscence: In 1979 I flight tested a Vortex that was reported to exhibit a turn. I flew it from a low hill and discovered that it did indeed tend to turn one way when flown ‘hands off’ (that is, by relaxing my grip on the control bar). In contrast, when I flared to land it, it dropped the opposite wing. It seemed likely to me that the bow strings needed adjusting. However, as was often the case in those days, I heard nothing more about it.

See also the Chargus of Buckinghamshire, England related topics menu.

This topic continues in Hang gliding 1978 and 1979 part 3.

External links

3 Decades of Liz by Liz Sharp as told to C.J. Sturtevant in Hang Gliding & Paragliding, May 2008

Grouse Mountain competition 1978: Names to Faces. The Challenge. Posted by Fred Wilson in 2014 on the Hanggliding.org forum, it attempts to identify the individuals in a group photo of about 70 top pilots from around the world. (Updated by this author in October 2020.)

1970s Found 8mm Film Home Movie – TORREY PINES HANG GLIDERS on YouTube starting at 1 minute 5 seconds, where George Worthington’s Cumulus VB with dragons painted on the sail appears; parked on the ground

References

1. My Life as a Hang Glider Maker by John LaTorre on his blog No truth to the rumor

2. Dove: Topic reply on British Hangies Facebook group

3. AeroStar Starcraft: Message from Cliff Whitney via this site’s contact form in May 2021

4. The Electra Flyer Floater, designed by Tom Price, omitted deflexor cables and relied instead on beefier leading edge tubes for strength: Steve Pearson e-mail exchange with the author in August 2021. See also Tom Price’s flying machines.

6. Sunbird Nova advert, Hang Gliding, June 1979

7. Steve Pearson e-mail exchange with the author in August 2021

8. Skydart by Ultra Light Flight Systems in Sydney, Australia in Australian Hang Gliding history Facebook group. Steve Cohen’s Skydart is claimed to be the first of the mid- to late 1970s reversion to deflexorless leading edge tubes.

Oh WOW…I had never seen a photo of Peghiny’s “Eagle” before. Amazing.

LikeLike

I have seen several photos of what appears to be the same glider, but it had a different name each time. The caption of that particular Bettina Gray photo called it the Eagle. Whatever it was called, it sure looked spectacular!

LikeLike

Update: The Eagle and Jaguar were different prototypes. Tom made the Eagle while at Seagull Aircraft. The later Jaguar bears hallmarks of Sky Sports manufacture.

LikeLike

In my experience Ravens would be out flown on light days by Moyes Maxis and out flown on strong days by the double surface ships. They did have a reputation for great handling. The Maxi dominated sink rate performance until the Atlas-Mega arrived.

LikeLike

Thanks for that counter-balancing insight. I have placed a link to your comment from farther up this page.

LikeLike